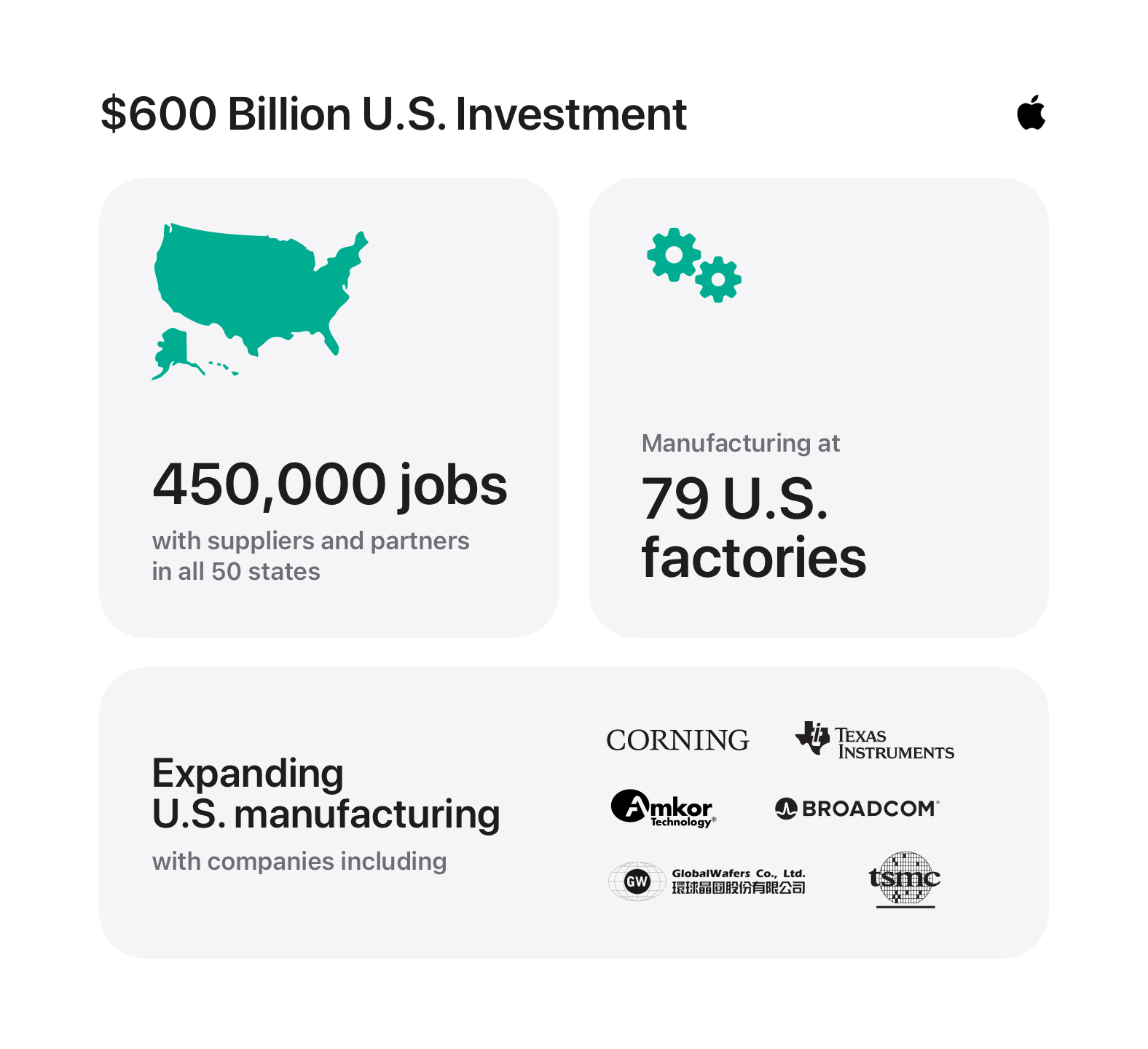

In a landmark announcement set to reshape the American tech landscape, Apple has pledged a staggering $600 billion investment in the United States, which promises to create numerous Apple investment jobs and support U.S. silicon production. Headlined by the new American Manufacturing Program (AMP), this Apple today announced a significant expansion of its U.S. operations for Apple investment jobs U.S. silicon, committing $600 billion over the next four years. A central part of this initiative is the new American Manufacturing Program (AMP), designed to onshore the production of critical components, including the glass for every iPhone and a complete, end-to-end supply chain for Apple silicon.

The announcement details extensive partnerships with U.S. suppliers, the expansion of multiple domestic facilities, and a plan that will support an estimated 450,000 American jobs as part of the Apple investment jobs U.S. silicon initiative.

The Investment: A $600 Billion U.S. Commitment

According to the official release, Apple’s investment will be distributed across its supply chain, R&D efforts, and direct hiring. The company plans to add 20,000 employees directly to its U.S. workforce over the next four years. The program involves manufacturing at 79 U.S. factories, demonstrating the focus on Apple investment jobs U.S. silicon.

“Today, we’re proud to increase our investments across the United States to $600 billion over four years and launch our new American Manufacturing Program,” Apple CEO Tim Cook stated in the announcement.

The American Manufacturing Program Explained

The AMP initiative is a coordinated effort to increase domestic production of key technologies. Apple, through the plan for Apple investment jobs U.S. silicon, is working with long-standing and new partners to achieve this. The program’s primary goals are:

- Producing all iPhone and Apple Watch cover glass in the U.S.

- Sourcing American-made rare earth magnets from key partners like MP Materials.

- Creating a complete, end-to-end silicon supply chain on American soil.

Onshoring Key Component Production

The plan outlines a clear strategy to bring complex manufacturing processes to the United States, emphasizing the creation of Apple investment jobs U.S. silicon.

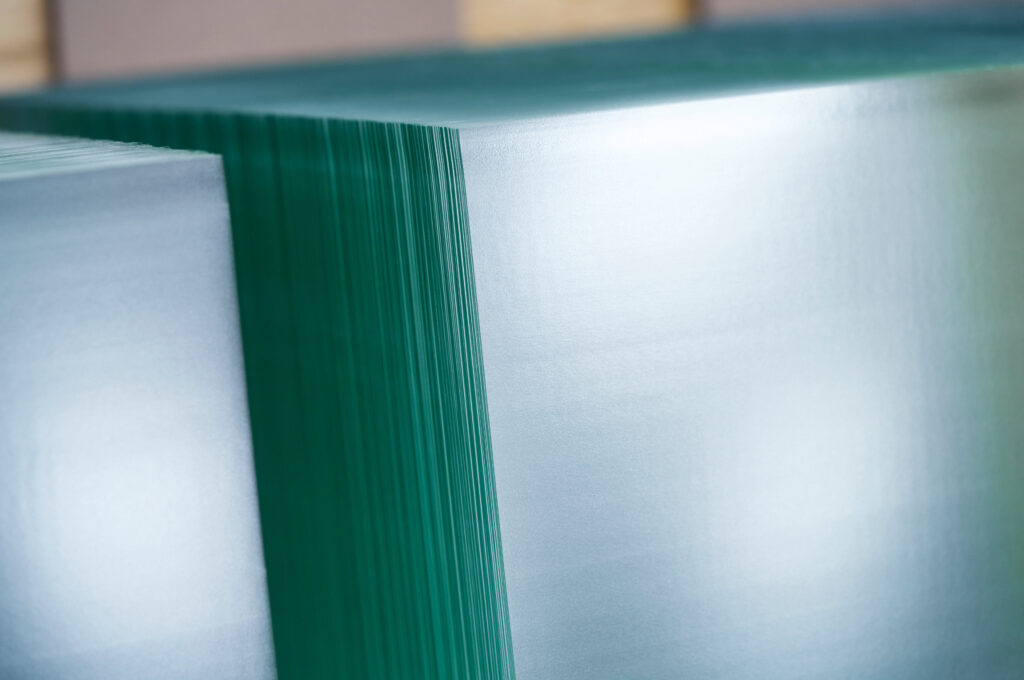

iPhone Glass Production Moves to Kentucky

Through an expanded partnership with Corning, all cover glass for Apple’s flagship products will now be produced at a state-of-the-art facility in Harrodsburg, Kentucky, showcasing the strategy behind Apple investment jobs U.S. silicon. This marks a significant shift for a high-volume, critical component.

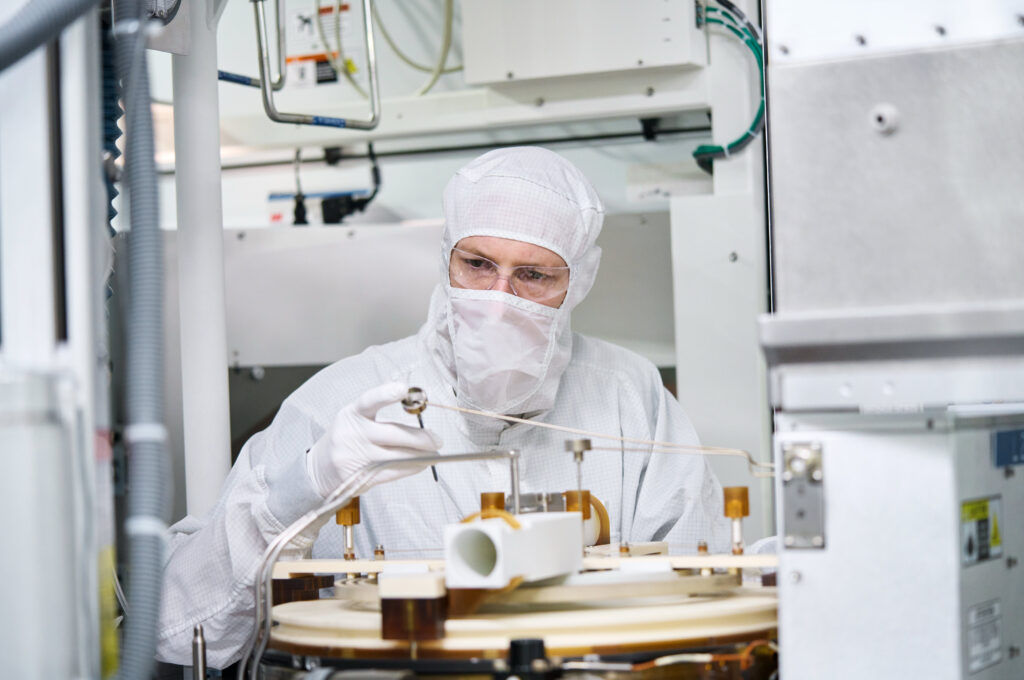

Establishing a U.S. End-to-End Silicon Supply Chain

Apple detailed a multi-state partnership to create a complete domestic supply chain for its chips:

- Wafers: GlobalWafers America will produce advanced 300mm silicon wafers in Sherman, Texas.

- Fabrication: TSMC‘s new fab in Arizona and Texas Instruments‘ facilities will use these wafers to manufacture chips for Apple products. Apple confirmed it is the first and largest customer for the TSMC Arizona facility.

- Packaging: Amkor will package the finished Apple silicon at its new facility in Arizona.

New Facilities to Power AI and R&D

The investment also funds the expansion of Apple’s physical infrastructure in the U.S. A new factory in Houston, Texas, has begun producing test units of advanced servers that will be essential for powering Apple Intelligence, underpinning efforts for Apple investment jobs U.S. silicon.

Additionally, Apple is expanding its major R&D campus in Austin, Texas, and increasing the capacity of its data centers in North Carolina, Iowa, and other states to support its growing services ecosystem.

Leave a Reply